close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-08-09 Origin: Site

Have you ever wondered how scientists measure the concentration of liquids?Refractometers are essential tools in labs, playing a crucial role in various industries. They help measure the purity and concentration of liquids and solids, ensuring quality control and accurate results.In this post, we’ll discuss how refractometers work, their importance in different fields, and how they contribute to industries like pharmaceuticals, food & beverage, and research.

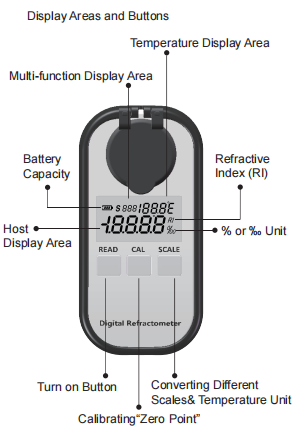

A refractometer is a device used to measure the refractive index (RI) of a substance. The refractive index describes how light bends when passing through a material. By measuring this bending, a refractometer can determine the concentration of a substance in a solution. The main components of a refractometer include a light source, a prism, and a scale (either analog or digital) to display the results.

Using the right lab equipment ensures accurate and reliable results. Refractometers are essential tools for precise measurements in various fields like food, pharmaceuticals, and chemical analysis. Without understanding how to use them properly, your measurements may be off, affecting research and product quality.

Refraction is the bending of light when it moves from one medium to another. This bending depends on the refractive index of the substance. Snell's Law helps us calculate the angle at which light bends, allowing us to determine the refractive index. This is the principle refractometers rely on to provide accurate measurements.

Prism: The prism is where the sample is placed, and it plays a key role in refracting the light.

Light Source: The light passes through the sample, bending depending on its composition.

Detection System: In analog refractometers, you look through an eyepiece to see the light/dark boundary. Digital refractometers use sensors to detect this boundary and show the result on a screen.

To use a refractometer, place a small amount of your sample on the prism. Ensure the sample covers the surface evenly. Then, direct the device towards a light source. The scale will either show a reading directly (analog) or display the result digitally. Adjust for temperature differences if needed.

Handheld analog refractometers are commonly used for fieldwork and in simple lab settings. They are portable and easy to operate, making them ideal for quick tests in less controlled environments. However, they are less accurate than digital models and may require manual adjustments for temperature changes.

Advantages:

Lightweight and portable.

Low cost compared to digital models.

Disadvantages:

Less precise.

May require manual temperature corrections.

Digital refractometers are known for their accuracy and user-friendly features. They automatically adjust for temperature variations, providing more consistent results. These models display measurements digitally, which is easier to read and interpret.

Common Features:

Automatic temperature compensation (ATC).

Quick, digital readouts.

Advantages:

High accuracy and precision.

Easy-to-read digital display.

Disadvantages:

More expensive than analog models.

Abbe refractometers are used in laboratories and industrial settings where precision is critical. They have a wide measurement range, allowing them to measure both liquids and solids. These refractometers are highly accurate but can be more complex to use.

Advantages:

High precision.

Wide measurement range.

Disadvantages:

Requires careful calibration.

More expensive and bulky.

Inline process refractometers are installed directly into manufacturing systems to monitor the refractive index of liquids in real time. They are used in industries like food processing and chemical manufacturing to ensure product quality during production.

How They Work:

Continuously monitor liquid concentration.

Integrated into production lines for real-time feedback.

Advantages:

Continuous monitoring.

Helps maintain product consistency during production.

Disadvantages:

Requires installation into industrial systems.

Higher initial cost.

Calibration is crucial for accurate refractometer measurements. If the device isn’t properly calibrated, the readings can be off, leading to incorrect results. Regular calibration ensures reliability in all types of testing, whether it’s for research or industrial applications.

How Calibration Helps:

Ensures accurate refractive index measurements.

Prevents errors caused by temperature variations or impurities.

Start by placing a drop of distilled water on the prism. This should set the refractometer to zero Brix, the baseline measurement for a pure solution.

For more specific calibrations, use substances like wort or sugar solutions. Place the sample on the prism and adjust the refractometer to match the known concentration of the substance.

Step-by-Step Calibration:

Clean the prism and apply the sample.

Adjust the refractometer until it reads the correct value.

Recheck the calibration if you notice any inconsistencies.

Maintaining your refractometer ensures it performs well over time. Regular cleaning and proper storage can prevent damage and ensure consistent accuracy.

Cleaning the Prism and Eyepiece:

Use a soft, lint-free cloth to clean the prism after each use.

Avoid abrasive materials, which can scratch the optical surface.

Preventing Contamination:

Make sure to remove any air bubbles from the sample to avoid distortion in measurements.

Clean the device thoroughly after using substances that might leave residues.

Proper Storage:

Store your refractometer in a protective case when not in use.

Keep it in a dry, clean environment to avoid dust and moisture buildup.

Refractometers are widely used in the food industry to measure sugar content in products like wine, beer, and syrups. The Brix scale, a key measurement on refractometers, helps determine the percentage of dissolved sugar in a solution. This is crucial for ensuring the consistency and quality of beverages and other food items.

Common Uses:

Measuring sugar content in wine and beer.

Checking syrup and fruit juice concentrations.

In laboratories, refractometers are used to test the purity of chemicals. By measuring the refractive index, scientists can identify impurities or verify the quality of a substance. This is particularly important in pharmaceuticals and chemical manufacturing, where purity is vital for safety and effectiveness.

How It Helps:

Detects impurities by comparing refractive index values.

Ensures chemicals meet industry standards.

Refractometers are essential in the pharmaceutical industry for determining the concentration of drug solutions. Accurate measurements of concentration are crucial for product consistency and quality control. The ability to monitor these levels ensures that medications are effective and safe for patients.

Applications:

Monitoring drug concentrations.

Verifying consistency in pharmaceutical production.

Refractometers also play a role in scientific research. They are used to study molecular interactions and properties of materials. By monitoring chemical reactions in real-time, researchers can gain insights into how substances behave under different conditions.

Research Uses:

Studying molecular interactions.

Monitoring chemical reactions in research labs.

Inconsistent readings are a common issue with refractometers. Calibration errors or temperature fluctuations can cause discrepancies in measurements. If your readings aren't consistent, it’s often due to the instrument being improperly calibrated or environmental factors affecting the sample.

Possible Causes:

Incorrect calibration.

Temperature variations.

Solutions:

Recalibrate the refractometer using distilled water or a known sample.

Ensure the sample and instrument are at a consistent temperature before use.

Air bubbles can distort the light path in a refractometer, leading to inaccurate readings. They create space between the prism and the sample, affecting light refraction.

How Bubbles Affect Results:

Air bubbles interfere with light, causing errors in the refractive index calculation.

How to Avoid Air Bubbles:

Gently tap the sample container to remove bubbles.

Use a syringe to carefully place the sample on the prism to avoid trapping air.

Dirt or residue on the prism or other optical parts can affect accuracy. It can block or scatter the light, distorting the readings.

How Dirt Affects Accuracy:

Contaminants on the prism lead to improper light transmission, which skews results.

Cleaning Tips:

Use a soft, lint-free cloth to clean the prism and eyepiece.

Clean the device after each use to prevent buildup.

Refractometers are popular in labs for several reasons. They are fast, accurate, and easy to use, making them ideal for quick measurements. They also require very small sample sizes, which reduces waste and cost. Modern refractometers have minimal temperature correction issues, making them more reliable and efficient in various conditions.

Advantages:

Quick and accurate measurements.

Small sample size needed.

Modern models require little to no temperature adjustments.

While refractometers offer many benefits, they do have some drawbacks. Calibration can be tricky, especially when measuring substances like alcohol in fermented samples. Without proper calibration, readings may be inaccurate, leading to unreliable results.

Disadvantages:

Calibration issues in certain applications (e.g., alcohol measurements).

Inaccurate readings if calibration is not done correctly.

The Brix scale measures the percentage of sucrose (sugar) in a solution. Refractometers use this scale to determine the sugar content, particularly in beverages like wine, beer, and fruit juices. The higher the Brix value, the sweeter the solution. It's crucial in food and beverage industries for quality control and consistency in production.

Why Brix is Important:

Measures sugar concentration.

Ensures consistency in food and beverage production.

Specific gravity measures the density of a liquid compared to water. A refractometer uses this scale to determine how much of a substance is dissolved in the liquid. Unlike the Brix scale, which focuses on sugar, specific gravity can be used to measure other substances like alcohol or salt content.

Differences from Brix:

Specific gravity measures overall density, not just sugar.

Brix is specifically for sugar solutions.

The Plato scale, similar to Brix, measures the concentration of extract (mainly sugar) in a solution. It's commonly used in the brewing industry to measure the strength of wort. While Brix and Plato are almost identical, they differ slightly in their calculation methods and applications.

Plato vs. Brix:

Plato is often used in brewing, while Brix is more common in general food and beverage testing.

The scales are nearly identical for practical purposes.

Refractometers play a crucial role in various industries, ensuring accurate measurements and product quality. From food production to pharmaceuticals, they help maintain consistency and purity. By understanding how to use refractometers properly, you can improve accuracy and efficiency in your lab work.

A: Yes, a Brix refractometer can be used for oil samples, but calibration may be needed to adjust for the different refractive properties of oils compared to sugar solutions.

A: Calibration should be done regularly, especially if the refractometer is used frequently or for different types of samples. For routine use, calibration once a day or before each use is recommended.

A: Yes, some refractometers are specifically designed to measure the salinity of water or other solutions, such as seawater or aquarium water.