close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

Expert Guide to a Refractometer: How It Works, Types, and Usage Have you ever wondered how scientists measure the concentration of substances in liquids? Refractometers are essential tools that provide these precise measurements.In this post, we’ll explain what a refractometer is and why it’s so important across various industries. You’ll also learn how refractometers work, the different types available, and their many uses in fields like food, medicine, and manufacturing.

Refraction occurs when light passes through one material and bends as it enters another. For example, when light travels from air into water, it slows down and changes direction. This bending is the key to how refractometers work.

The amount of bending depends on the refractive index of the material. The higher the refractive index, the more the light bends. Refractometers measure this bending to determine the concentration of a substance in a solution. This refractive index helps identify properties like sugar content or salinity.

Prism: The prism is a crucial part of the refractometer. When a sample is placed on the prism, light is directed through it. The angle at which light bends is recorded, allowing the refractometer to determine the refractive index.

Light Source: The light source shines through the sample on the prism. It’s essential for providing consistent lighting during measurements. Without a stable light source, the results could be inaccurate.

The Measuring Scale: For analog refractometers, the scale shows where the light and dark areas meet. This point indicates the refractive index. Digital models display the refractive index directly on a screen, making it easier to read the results.

Handheld refractometers are compact and easy to use, perfect for quick measurements in the field. Their portability makes them ideal for on-the-spot testing, and they don’t require electricity to operate.

These refractometers are commonly used in industries like brewing, winemaking, and food processing. They allow for fast, reliable measurements of sugar content (Brix scale) and other substances in liquids, making them essential tools for quality control.

Abbe refractometers are laboratory-grade instruments designed for high-precision measurements. They offer greater accuracy compared to handheld models, making them ideal for scientific and industrial applications.

Typically used in research, chemical analysis, and pharmaceuticals, these refractometers are perfect for detailed, high-accuracy work. They help ensure precise measurements of refractive indices in various substances.

Digital refractometers offer enhanced accuracy and ease of use over traditional analog models. Instead of reading from a scale, results are displayed directly on a digital screen, eliminating human error.

One standout feature is automatic temperature compensation (ATC), which ensures consistent results even when temperature fluctuates. These refractometers are widely used in medical diagnostics, agriculture, and automotive fluid analysis for tasks like determining the concentration of body fluids or testing coolant levels.

Inline refractometers are designed for continuous monitoring in industrial settings. These devices are directly installed into production lines, allowing real-time analysis of liquids without disrupting the workflow.

Industries like food processing, pharmaceuticals, and chemical manufacturing rely on inline refractometers for process control and maintaining consistent quality. They provide constant feedback and help ensure that production processes stay on track.

Brix Refractometers: Used extensively in the food and beverage industry, these refractometers measure the sugar content in liquids, especially fruit juices, wine, and syrups.

Gemological Refractometers: These specialized refractometers are designed for identifying gemstones. They measure the refractive index to help distinguish between different types of stones.

Salinity Refractometers: These are commonly used in marine and aquarium industries to measure the salt content in water, ensuring the proper conditions for marine life.

Calibration

To start, calibrate your refractometer using distilled or deionized water. Place a few drops of water on the prism and close the cover. Look through the eyepiece or digital display and adjust the calibration screw until the reading shows zero. This step ensures your readings will be accurate.

Sample Preparation

After calibration, place a few drops of your sample onto the prism. Be careful not to overload the prism. Close the cover gently to spread the sample evenly and avoid air bubbles, which can affect the measurement.

Taking the Measurement

With the sample in place, hold the refractometer up to a light source. Look through the eyepiece or digital display. The refractometer’s scale will show where the light and dark areas meet, or the digital screen will directly show the refractive index. This is your measurement.

Keep the Prism Clean

A clean prism is essential for accurate results. Any dirt or residue can interfere with light passing through the sample and give inaccurate readings. Wipe the prism with a soft, lint-free cloth between uses.

Use Proper Light Sources

Natural light or a stable light source works best for refractometer measurements. Avoid using fluorescent light, as it can cause inconsistent readings.

Ensure Temperature Stability

Temperature can affect readings. To get the most accurate results, make sure your sample and refractometer are at a stable, consistent temperature. If using a digital refractometer, models with automatic temperature compensation (ATC) can help adjust for temperature changes.

Refractometers are widely used in the food and beverage industry to measure the sugar content in liquids. The Brix scale helps determine the concentration of sugar in juices, wines, and soft drinks. This is essential for quality control and consistency.

Other applications include measuring sugar levels in jams, syrups, and honey production. By testing these products, manufacturers can ensure their consistency, quality, and sweetness.

In the automotive industry, refractometers are used to measure the concentration of coolant in a vehicle's radiator. This ensures the proper freezing point, preventing damage in cold weather.

Additionally, they help monitor battery fluid levels, which is crucial for maintaining the performance and longevity of car batteries.

In clinical labs, refractometers measure the specific gravity of urine, which helps diagnose dehydration and kidney problems. They also measure serum protein concentration, which is vital for monitoring patients' health.

These devices are a reliable tool in diagnostics, offering fast and precise readings for healthcare providers.

Refractometers play a key role in monitoring concentrations in chemical production. They ensure that the desired concentrations of chemicals are maintained, which is crucial for safety and product quality.

In food processing and pharmaceuticals, inline refractometers provide real-time monitoring of ingredients, ensuring consistent product quality throughout the manufacturing process.

In agriculture, refractometers are used to determine the ripeness of fruits by measuring sugar content. This helps farmers decide the best time for harvesting crops like grapes, apples, and oranges.

In beekeeping, refractometers are essential for monitoring moisture levels in honey, ensuring that it meets quality standards and is safe for consumption.

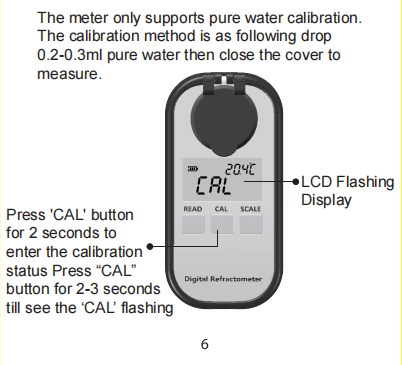

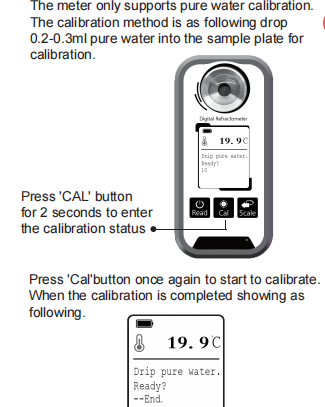

Calibrating your refractometer ensures accurate measurements every time. Here's a simple step-by-step guide:

Clean the Prism: Use a soft cloth to clean the prism before calibration.

Apply Distilled Water: Place a few drops of distilled or deionized water on the prism.

Close the Cover: Ensure the cover plate is properly sealed to spread the water evenly.

Adjust the Calibration Screw: Look through the eyepiece or digital display and adjust the screw until the scale shows zero. For digital models, follow the manufacturer's instructions.

Test Calibration: After calibration, check the refractometer with a known standard (like distilled water) to ensure it reads accurately.

Regular calibration is key to maintaining precision, especially after prolonged use or environmental changes.

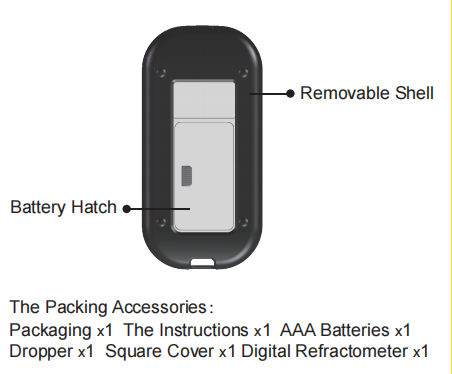

To keep your refractometer working smoothly, proper maintenance is essential:

Cleaning Tips: Always clean the prism after every use. Use a soft, lint-free cloth to remove any residue. For stubborn stains, use a gentle cleaning solution and wipe dry.

Storage: Store your refractometer in a dry, cool place when not in use. Avoid exposing it to extreme temperatures or humidity. Using a protective case helps prevent damage during storage or transport.

There are several reasons your refractometer might give inaccurate readings:

Contaminated Samples: If the sample is not clean or has residues, it can interfere with the light passing through, leading to wrong results.

Incorrect Calibration: If the refractometer is not calibrated correctly, the readings may be off. Make sure to calibrate it regularly with distilled water or a known standard.

Environmental Factors: Temperature fluctuations or improper lighting can affect measurements. Ensure a stable environment for optimal results.

Here are some common issues and how to fix them:

Calibration Failure: If the refractometer doesn't read zero after calibration, check the calibration process or try recalibrating with fresh distilled water.

Broken Prisms: A cracked or scratched prism can lead to faulty readings. If this happens, it’s best to replace the prism or contact the manufacturer for repairs.

What to Check: Before calling customer support, make sure the refractometer is clean, calibrated, and the sample is free from contamination. If the issue persists, it may be time to seek professional help.

Refractometers play a crucial role across industries, providing precise measurements for quality control. They help ensure consistency in fields like food, automotive, and healthcare.

Investing in a reliable refractometer ensures accurate results, improving efficiency in everyday operations.For quality refractometers, consider purchasing from trusted suppliers or manufacturers who offer reliable products and support.

A: Refractometers measure the refractive index to determine substance concentration, offering more accuracy. Hydrometers, based on buoyancy, are less precise and affected by temperature and impurities.

A: Consider the application, type of substance, and required precision. Handheld models are great for quick field tests, while laboratory models offer higher accuracy.

A: Most refractometers measure liquids like juices, wine, and coolants, but some liquids (like oils) may require specialized models due to their refractive properties.

A: Refractometers are highly accurate, often within 0.1-0.2%. Regular calibration ensures continued precision.

A: Common scales include Brix (for sugar content), Plato (for brewing), and refractive index (for general concentration measurements).