close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-08-07 Origin: Site

Ever wondered why refractometer readings sometimes don’t match expectations? Inaccurate sample preparation could be the culprit. Refractometersplay a key role in industries like food, beverages, and pharmaceuticals, helping ensure product consistency. However, proper sample preparation is crucial for accurate results. In this article, we’ll discuss the top tips for preparing samples and taking precise refractometer readings to improve your quality control process.

A representative sample is crucial for accurate refractometer results. It should reflect the overall material or product you're testing. Whether it’s a liquid or solid, ensure the sample size is sufficient and free from contaminants. For liquids, take a homogenous portion, while for solids, choose a piece that truly represents the whole batch.

Degassing removes excess gas from carbonated beverages before measurement. If not degassed, carbonation can interfere with the refractometer’s readings. To degas, simply pour the liquid between containers or allow it to sit in an open container for a short period. This step ensures accurate sugar measurements, especially for drinks like soda or sparkling water.

When measuring viscous or semi-solid samples, heating is necessary. Materials like fats, waxes, or oils need to be melted to flow easily and form a uniform sample. Heating ensures the refractive index is consistent across the entire sample, which is key for accurate readings. Always monitor the temperature to avoid overheating and altering the sample’s properties.

For fruit-based samples, removing unwanted parts like seeds and pulp is essential. These solids can skew refractometer readings by disrupting the uniformity of the sample. After removing these components, crush or grate the fruit to ensure an even, homogeneous sample. This step minimizes variability, ensuring consistent and accurate results.

Non-liquid samples, like vegetables or solid food products, require proper homogenization. Crushing, grating, or blending helps break down the material, ensuring it’s uniform throughout. This prevents uneven refractive index readings, giving you more accurate and reliable results. Consistency in sample preparation is key for obtaining precise measurements.

Temperature plays a significant role in refractometer readings. If the sample isn't at the right temperature, it can lead to inaccurate results. Allow your sample to reach a stable temperature before taking the reading. This ensures the refractive index is measured correctly. Let the sample and refractometer adjust to the same temperature, ideally around 20°C, to minimize errors.

Cleaning the refractometer prism is crucial between measurements. Any leftover sample can contaminate the next one, leading to faulty readings. Use a soft, lint-free cloth to gently clean the prism. For thorough cleaning, use solvents like water, ethanol, or acetone. Make sure the prism is completely dry before applying the next sample to avoid cross-contamination.

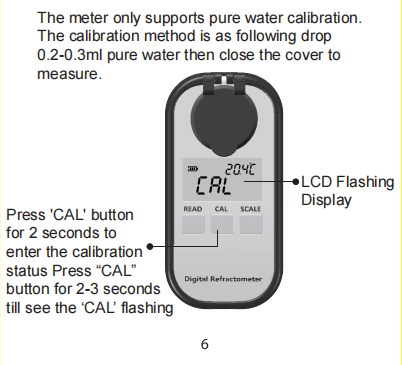

Regular calibration is essential for reliable refractometer readings. Before using your instrument, calibrate it using distilled water or a known standard. This step helps correct any potential drift in the instrument’s accuracy. Calibration ensures consistent and accurate measurements every time you use your refractometer.

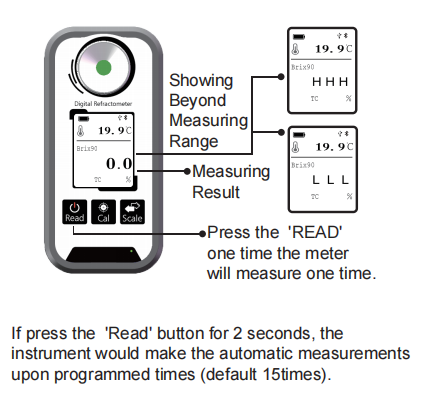

To achieve precise readings, apply just a few drops of your sample to the refractometer prism. Ensure the sample covers the prism evenly, avoiding air bubbles. This simple step guarantees the light passes through the sample consistently, resulting in more accurate refractive index measurements.

Optical and digital refractometers work differently but serve the same purpose. Manual refractometers use light and scale readings, while digital ones offer an automated display. Digital refractometers are often more accurate and easier to use, while manual ones are cost-effective and portable. Choose based on your application and the level of precision needed.

Using the correct amount of sample is key to accurate readings. Too much sample can cause longer stabilization times, while too little leads to uneven readings. Ensure your sample covers the prism evenly without overfilling. If possible, use the presser or plate provided with your refractometer to control the sample size.

Syrups and concentrates can form a thick, highly concentrated layer on top, called "skin." This can lead to inaccurate refractometer readings. To prevent this, stir the sample thoroughly to mix the layers well. Avoid stirring too aggressively to prevent air bubbles, which can also distort results.

Hot samples, like molten wax or hot oils, require special care. These materials can easily change their properties when cooled. Use temperature compensation techniques to adjust readings to a standard temperature, usually 20°C. If you’re measuring hot samples, elevate your refractometer to match the sample’s temperature before taking measurements.

Temperature has a big impact on refractometer readings, especially for non-sugar samples like oils or juices. These substances respond differently to temperature changes compared to sugary liquids. High-quality digital refractometers often feature temperature compensation for more accurate measurements. This ensures the refractive index is calculated correctly, regardless of temperature shifts.

Temperature instability can lead to fluctuating refractometer readings. To prevent this, ensure the sample is fully stabilized before measurement. Allow it to sit for a few minutes until it reaches a steady state. Many modern refractometers have built-in stability checks, which ensure the sample and instrument have reached the proper temperature before displaying the reading.

Cleaning your refractometer regularly is key to avoiding cross-contamination between samples. Even small residues can affect subsequent readings, leading to inaccurate results. After each use, wipe the prism and plate with a soft, lint-free cloth. Periodically inspect the instrument for any signs of wear or damage. Following proper maintenance routines will ensure it continues delivering accurate measurements over time.

To maintain reliable readings, regularly check your refractometer’s performance. This involves calibrating it before use, especially if it’s been exposed to different conditions. Calibration should be done at least once a day, or more frequently if the instrument is used intensively. Use distilled water or known standards for calibration, and always verify the performance with appropriate reference materials.

Preventative maintenance contracts are a great way to keep your refractometer in top shape. Regular check-ups by the supplier ensure the instrument is calibrated and cleaned properly. This proactive approach minimizes the risk of equipment failure and ensures consistent performance, ultimately leading to more accurate readings and fewer disruptions in your work.

To achieve accurate refractometer readings, ensure proper sample preparation, correct application, and routine maintenance. Regular cleaning and calibration are crucial for reliable results. Investing in a quality refractometer and following best practices is key to consistency. By adopting these tips, you’ll maintain high performance and reliable readings in your measurements.

A: If the reading seems off, first check if the sample is at the correct temperature and that it’s evenly applied to the prism. Clean the prism to remove any residue, and recalibrate the refractometer using a known standard. If problems persist, inspect the refractometer for any damage or malfunction.

A: Regular cleaning of the prism and plate with a soft cloth is essential. Use appropriate solvents like water or ethanol, and perform periodic calibrations to ensure accurate results. Store the refractometer in a safe, dry place to avoid damage.

A: Yes, but make sure to clean the refractometer thoroughly between samples to prevent cross-contamination. This is especially important when measuring different materials or substances to ensure accurate readings.