close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-08-06 Origin: Site

Have you ever wondered how to measure the concentration of a liquid with precision? A refractometer is the key tool that can do just that. It is used in various industries such as food production, chemistry, and agriculture to ensure accuracy.In this article, we'll explore what a refractometer is and why understanding its usage is essential. You'll learn how it helps measure the purity and concentration of solutions with ease and precision.

A refractometer is an optical instrument used to measure the concentration of substances in liquids. It works by evaluating how light bends, or refracts, when it passes through a sample. This bending occurs because light travels at different speeds in different mediums.

When light passes through a liquid, it changes direction due to the liquid's refractive index. A refractometer measures this change in direction, providing a reading that indicates the concentration of the substance. The higher the refractive index, the more concentrated the solution.

Refractometers come in different types, including:

Handheld Analog Refractometers: Portable devices commonly used for quick, field measurements. They're ideal for measuring sugar content in fruit juices, honey, or other liquids.

Digital Refractometers: These devices provide more precise and automated readings, often with temperature compensation.

Bench-top Refractometers: Used in labs for high-accuracy measurements. These models are more complex and often feature higher precision.

Refraction is the bending of light as it passes from one medium to another. This happens because light travels at different speeds in different materials. In the case of a refractometer, light bends when it moves from air into the sample liquid, allowing the instrument to measure the angle of this change.

The refractive index is a measure of how much a substance can bend light. It varies with the concentration of dissolved substances in the liquid. By knowing the refractive index of a solution, we can estimate the amount of dissolved solute. For example, a higher refractive index typically means a higher concentration of sugar or salt in the liquid.

Calibration ensures your refractometer gives accurate readings. If it’s not calibrated, measurements might be off, leading to unreliable results. Calibration also accounts for temperature variations, ensuring precise measurements every time.

Clean the Prism: Wipe it with a soft, lint-free cloth to remove any dust or residue.

Use Distilled Water: Place a drop of distilled water on the prism. This provides a baseline, usually set to a refractive index of 1.0.

Adjust the Calibration Screw: Look through the eyepiece. Adjust the screw until the boundary line between the light and dark areas lines up with the 0% or 1.0 mark.

Check Calibration: Repeat this process a couple of times to ensure accuracy.

Place a few drops of the liquid sample directly on the refractometer's prism. Be sure to spread the liquid evenly for a consistent measurement. Close the cover to ensure a thin, uniform layer of the sample.

Look through the eyepiece. The scale will show a boundary between a light and dark area. The point where the boundary intersects the scale gives you the measurement. This tells you the concentration of the substance in the liquid, whether it’s sugar, salt, or other solutes.

Digital refractometers offer greater precision and ease of use. Unlike handheld models, they automatically compensate for temperature changes, giving you a more accurate reading without manual adjustments. They also display the results digitally, making them easier to interpret.

Prepare the Sample: As with handheld models, apply a drop of the liquid onto the prism.

Turn on the Device: Power it up and wait for the reading to stabilize.

Read the Digital Display: The device will automatically show the refractive index or concentration level directly on the screen. No need for manual scale reading.

Refractometers are widely used to measure sugar concentration in liquids. For example, in fruit juices, honey, and syrups, they help determine sweetness levels. The Brix scale is commonly used, where higher Brix values indicate higher sugar content.

In food production, refractometers ensure consistent quality. They help manufacturers maintain the right balance of ingredients in beverages, dairy, and syrups. By measuring the concentration of key components, it ensures the final product matches quality standards.

Farmers use refractometers to measure the sugar content in fruits. This is essential for determining the optimal harvest time. For instance, high sugar levels in grapes indicate that they’re ready for winemaking.

Refractometers play a key role in winemaking. They measure grape maturity by assessing sugar concentration. This helps winemakers decide the right time for harvest, ensuring the best quality wine.

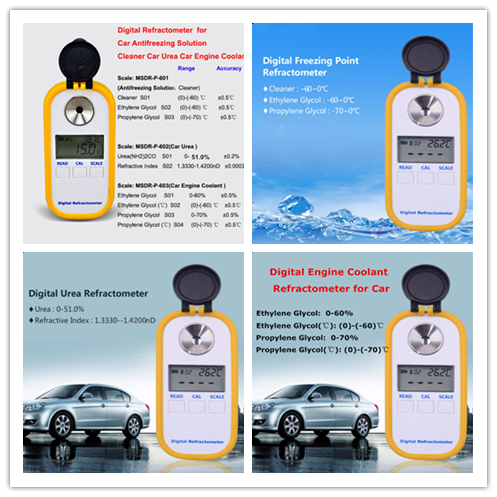

In vehicles, refractometers measure the concentration of antifreeze in the cooling system. Proper antifreeze concentration prevents engine damage by ensuring the fluid performs well under varying temperatures.

In healthcare, refractometers are used to measure the specific gravity of urine and serum. This helps diagnose conditions like dehydration or kidney disease, providing valuable insights into a patient’s health.

An Abbe refractometer is a precise laboratory-grade instrument used to measure the refractive index of liquids and solids. It’s commonly used in research and industrial settings where high accuracy is needed. These devices can measure both the refractive index and other optical properties, which makes them essential for scientific experiments and quality control.

Handheld refractometers are portable and perfect for fieldwork. Whether you're testing sugar content in fruits or measuring the salinity of water, these devices provide quick, reliable results. However, they may not be as precise as laboratory models and may require more frequent calibration. They’re ideal for situations where portability and ease of use are key.

Digital refractometers offer more precise readings and often come with automatic temperature compensation, which is great for accuracy. They are easier to use since they display results on a screen, eliminating the need to read scales manually. On the other hand, analog refractometers may require more hands-on effort but are often simpler and more affordable.

Inline refractometers are designed for continuous measurement in industrial settings. They are installed directly in production lines or pipelines. These devices offer real-time feedback, which is crucial for maintaining consistent product quality, such as in beverage manufacturing or chemical processing.

To maintain accurate readings, keep the prism clean. After every use, wipe it gently with a soft, lint-free cloth. Avoid using harsh chemicals, as they could damage the lens. For stubborn residues, use distilled water to clean the prism surface and ensure no debris is left behind.

Calibration frequency depends on how often you use the device. As a general rule, calibrate your refractometer before each major measurement session. If you use it frequently or notice fluctuations in readings, it’s a good idea to calibrate it more often.

If you notice inaccurate readings, first check if the prism is clean. A dirty prism can lead to wrong measurements. Ensure the instrument is properly calibrated and consider recalibrating if necessary. Also, check for any visible damage to the refractometer.

Temperature can significantly affect the refractive index. If the liquid sample is too warm or too cold, it might not give an accurate reading. Many modern refractometers come with automatic temperature compensation, but if yours doesn't, you’ll need to ensure the sample and instrument are at the same temperature.

The Brix scale is used to measure the sugar content in liquids, typically expressed as degrees Brix (°Bx). One degree Brix equals 1 gram of sucrose in 100 grams of solution. This scale is commonly used in industries like food and beverage production, especially for fruit juices, syrups, and honey, to assess sweetness levels.

Each of these scales measures solute concentration but in different ways.

Brix Scale measures sucrose (sugar) content, mainly used in food and beverages.

Plato Scale is used mainly in the brewing industry to measure the concentration of extract in wort (the liquid extracted from malted barley).

Baumé Scale is used in both the food and chemical industries to measure the density of liquids. It's most useful for solutions denser than water, such as saltwater or sugar solutions.

Refractometers can be used to measure the salinity of a solution, like brines or seawater. By measuring how light bends in the sample, the refractive index can be converted into a salinity value. Salinity refractometers are calibrated specifically for measuring the concentration of salt, and they are commonly used in food processing, marine biology, and water treatment.

Refractometers are essential tools for measuring concentration in various liquids. We’ve discussed how they work, their different types, and their use in industries like food, agriculture, and automotive. Calibration, maintenance, and understanding scales like Brix and Plato are key to accurate readings.

When choosing a refractometer, consider your specific needs, such as portability, precision, and the type of measurement required. Select one based on the industry you work in and the substances you measure.

A: Refractometers can be used for a wide range of liquids, including water-based solutions, oils, and alcohol. However, they are most accurate for liquids with a known refractive index. Specialized refractometers may be required for certain substances.

A: Refractometers offer high accuracy, but their precision depends on the model and calibration. Digital refractometers are generally more accurate than handheld models and often include temperature compensation.

A: Handheld refractometers typically cost between $50 and $300, while digital and laboratory models can range from $200 to over $1,000, depending on features and precision.